Sycamore Intl.: Keeping E-Waste out of Landfills

Mar 04, 2024

What do consumers, schools, companies, and organizations do when electronic devices and gadgets stop working or become obsolete? Unfortunately, America has garnered a reputation as a “throw-away society.”

The World Health Organization stated that E-waste is the fastest-growing solid waste stream in the world.

Over the last few years, the media has used the term “E-Waste” to report growing health and environmental issues. Electronic devices contain hazardous chemicals that can contaminate soil and pollute our water and air when not properly disposed.

According to The World Counts, "The world generates around 40 million tons of electronic waste every year, worldwide. That is like throwing away eight hundred laptops every second.” Some startling facts:

Steve Figgatt spent his summers working in an IT job at a local PA school district. He witnessed first-hand the challenges K-12 schools faced to responsibly recycle their electronic equipment.

The World Health Organization stated that E-waste is the fastest-growing solid waste stream in the world.

Over the last few years, the media has used the term “E-Waste” to report growing health and environmental issues. Electronic devices contain hazardous chemicals that can contaminate soil and pollute our water and air when not properly disposed.

According to The World Counts, "The world generates around 40 million tons of electronic waste every year, worldwide. That is like throwing away eight hundred laptops every second.” Some startling facts:

- An average cellphone user replaces their unit once every 18 months.

- E-waste comprises 70% of our overall toxic waste.

- Only 12.5% of E-Waste is recycled.

- Electronics contain lead which can damage our central nervous system and kidneys.

- E-waste contains hundreds of substances, of which many are toxic. This includes mercury, lead, arsenic, cadmium, selenium, chromium, and flame retardants.

Steve Figgatt spent his summers working in an IT job at a local PA school district. He witnessed first-hand the challenges K-12 schools faced to responsibly recycle their electronic equipment.

“I FOUNDED SYCAMORE INTERNATIONAL IN JUNE 2010. I REALIZED THERE WAS UNREALIZED VALUE IN THE DOWNSTREAM SUPPLY CHAIN, SO WE FOCUSED ON RE-PURPOSING SOME OF THE HARDWARE.”

Sycamore International is based in West Grove, PA, and for the past 14 years has been helping schools and organizations reclaim their value from laptops, desktops, phones, tablets, and servers. “Sycamore grew around the concept of refurbishing functional devices for reuse and responsibly recycling truly obsolete devices,” explains Figgatt. “We scaled up our operations over time from a garage to larger rented warehouse facilitates before settling in our 16-acre processing complex in West Grove. We now operate a fleet of trucks serving hundreds of large organizations across the mid-Atlantic and northeast of the United States.”

Sycamore International employs seventy experts who implement the valuable services organizations need to manage the challenges of electronic disposal.

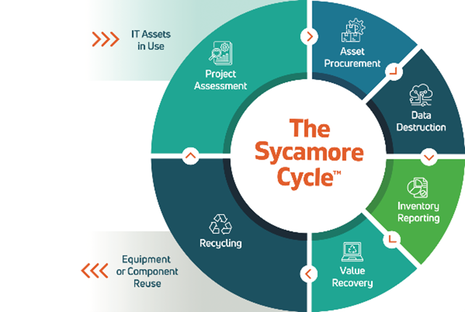

Sycamore’s Information Technology Asset Disposition (ITAD) Services include everything from pickup and packaging of the devices and hardware to data destruction and shredding. Sycamore will evaluate the inventory needed to be discarded and follow the proper due diligence to determine if the piece can be salvaged and refurbished.

Sycamore’s Information Technology Asset Disposition (ITAD) Services include everything from pickup and packaging of the devices and hardware to data destruction and shredding. Sycamore will evaluate the inventory needed to be discarded and follow the proper due diligence to determine if the piece can be salvaged and refurbished.

HARD DRIVES SHREDDED BY SYCAMORE INTERNATIONAL

Every piece of electronic equipment has stored data that can create security nightmares for companies and organizations. Sycamore meets or exceeds the NIST 800-88 and DoD 5220.22-M standards for data security.

In addition to removing any stickers and labels, “All data is digitally destroyed on storage mediums using a variety of methods to overwrite the entirety of standard platter drives repeatedly, followed by final verification steps. Data on solid-state drives is accomplished through a similar, but slightly different encryption-based overwriting process, depending on the specific model. For Apple products, we will coordinate with your staff to ensure they can successfully dis-enroll all devices from your DEP system (if applicable) ideally prior to equipment removal, as well as ensuring iCloud removal, which is necessary for effective data destruction.”

Sycamore technicians will test all the pieces and provide a report on functionality and condition. Any pieces that are not salvageable will be safely recycled.

In addition to removing any stickers and labels, “All data is digitally destroyed on storage mediums using a variety of methods to overwrite the entirety of standard platter drives repeatedly, followed by final verification steps. Data on solid-state drives is accomplished through a similar, but slightly different encryption-based overwriting process, depending on the specific model. For Apple products, we will coordinate with your staff to ensure they can successfully dis-enroll all devices from your DEP system (if applicable) ideally prior to equipment removal, as well as ensuring iCloud removal, which is necessary for effective data destruction.”

Sycamore technicians will test all the pieces and provide a report on functionality and condition. Any pieces that are not salvageable will be safely recycled.

ONE OF SYCAMORE’S CUSTOM BUILT DATA WIPING SERVERS. EACH IS CAPABLE OF WIPING 320+ DRIVES CONCURRENTLY.

“Over 80% of our revenues are derived by refurbishing electronics for further reuse. Sustainable business was always a core of our mission.”

World Counts reports that “85% of our E-Waste are sent to landfills and incinerators are mostly burned and release harmful toxins in the air!”

Sycamore can proudly state that “No equipment received by Sycamore goes to a landfill,” as proof in these certification details,” all equipment is sorted and recycled inside of our secure R2-certified facility in accordance with R2v3 (Sustainable Responsible Electronics Recycling), ISO 9001 (Quality Management), ISO 14001 (Environmental Management), and ISO 45001 (Occupational Health and Safety) standards.”

World Counts reports that “85% of our E-Waste are sent to landfills and incinerators are mostly burned and release harmful toxins in the air!”

Sycamore can proudly state that “No equipment received by Sycamore goes to a landfill,” as proof in these certification details,” all equipment is sorted and recycled inside of our secure R2-certified facility in accordance with R2v3 (Sustainable Responsible Electronics Recycling), ISO 9001 (Quality Management), ISO 14001 (Environmental Management), and ISO 45001 (Occupational Health and Safety) standards.”

SYCAMORE IS ALSO THE FIRST INFORMATION TECHNOLOGY ASSET DISPOSITION FACILITY IN THE WORLD TO OPERATE A SOLAR MICROGRID WAREHOUSE.

TWO ESS ENERGY WAREHOUSE LONG DURATION ENERGY STORAGE IRON FLOW BATTERIES USED TO OPERATE A MICROGRID, PEAK LOAD SHAVE AND PARTICIPATE IN ANCILLARY GRID SERVICES AT SYCAMORE INTERNATIONAL.

“In collaboration with Terra Sol Energies, we pioneered distributed renewable energy development by installing and operating the first solar microgrid coupled with an ESS Energy Warehouse Iron Flow Battery in the Eastern US. As we developed and optimized this system design, we've demonstrated that distributed domestic renewable energy production coupled with energy storage is completely commercially viable today.

Steve Figgatt found out about the World Trade Center of Greater Philadelphia’s Selling to the World Program through the Chester County Economic Development Council.

“We were doing some international direct sales to customers in the UK and UAE prior to engaging with WTCGP.”

Ron Drozd, WTCGP's Chief Operating Officer (At the time: Director of Export Program and Services), led the Selling to the World Export Training Classes designed to restore and expand the growth of small and medium-sized enterprises (SMEs), both established exporters and new-to-exporting companies, including increasing global access for minority and women-owned businesses (MWBEs). Sycamore International was one of eighteen companies to complete the export training course.

“Sycamore also attended our Bringing the World to PA meetings where they met with Pennsylvania Authorized Trade Representatives from Mexico, South Africa, Singapore (ASEAN), Czech Republic, and Central and Eastern Europe,” explains Drozd. “We also are glad Steve attended the Great Lakes St. Lawrence Governors and Premiers (GSGP) PA Trade Mission to South Africa where we set up about six meetings with potential buyers.”

“My experience with the WTCGP has been great based on what I've participated in thus far,” says Figgatt. “We're doing $2 million in direct international sales in the UK and UAE as of Q4 2023. Our sales team is working to establish a reliable supply chain of distributors in growth markets around the world.”

Most importantly, “Our thoughtful team fully embraces Circular Economy principles in our business model.

Sycamore’s annual e-scrap processing capacity is twenty million pounds, and they handle approximately 40,000 devices a month.

Steve Figgatt found out about the World Trade Center of Greater Philadelphia’s Selling to the World Program through the Chester County Economic Development Council.

“We were doing some international direct sales to customers in the UK and UAE prior to engaging with WTCGP.”

Ron Drozd, WTCGP's Chief Operating Officer (At the time: Director of Export Program and Services), led the Selling to the World Export Training Classes designed to restore and expand the growth of small and medium-sized enterprises (SMEs), both established exporters and new-to-exporting companies, including increasing global access for minority and women-owned businesses (MWBEs). Sycamore International was one of eighteen companies to complete the export training course.

“Sycamore also attended our Bringing the World to PA meetings where they met with Pennsylvania Authorized Trade Representatives from Mexico, South Africa, Singapore (ASEAN), Czech Republic, and Central and Eastern Europe,” explains Drozd. “We also are glad Steve attended the Great Lakes St. Lawrence Governors and Premiers (GSGP) PA Trade Mission to South Africa where we set up about six meetings with potential buyers.”

“My experience with the WTCGP has been great based on what I've participated in thus far,” says Figgatt. “We're doing $2 million in direct international sales in the UK and UAE as of Q4 2023. Our sales team is working to establish a reliable supply chain of distributors in growth markets around the world.”

Most importantly, “Our thoughtful team fully embraces Circular Economy principles in our business model.

Sycamore’s annual e-scrap processing capacity is twenty million pounds, and they handle approximately 40,000 devices a month.